What is a digital twin?

The added value of our 'Digital Twin'

There is so much marketing jargon these days that it’s hard for us to use the term Digitized or “Digital Twin” without feeling like we’re trying to impress with hollow terms. That is why we have decided to explain a term often used by Autarco such as ‘Digital Twin’ in layman terms.

The added value of Autarco’s ‘Digital Twin’ is that it allows us to actively measure the weather-dependent performance of the system at 15-minute intervals. This accurate performance analysis allows us to verify whether installations are performing as expected. If this is not the case, we can respond quickly to problems through timely detection. The end result is an average performance improvement of 8% for residential PV systems and a 5% improvement for commercial systems.

What is the "Digital Twin"

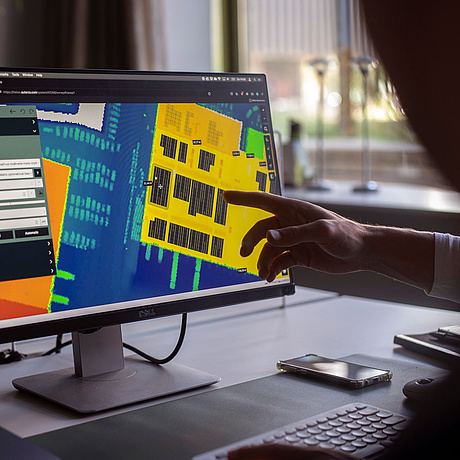

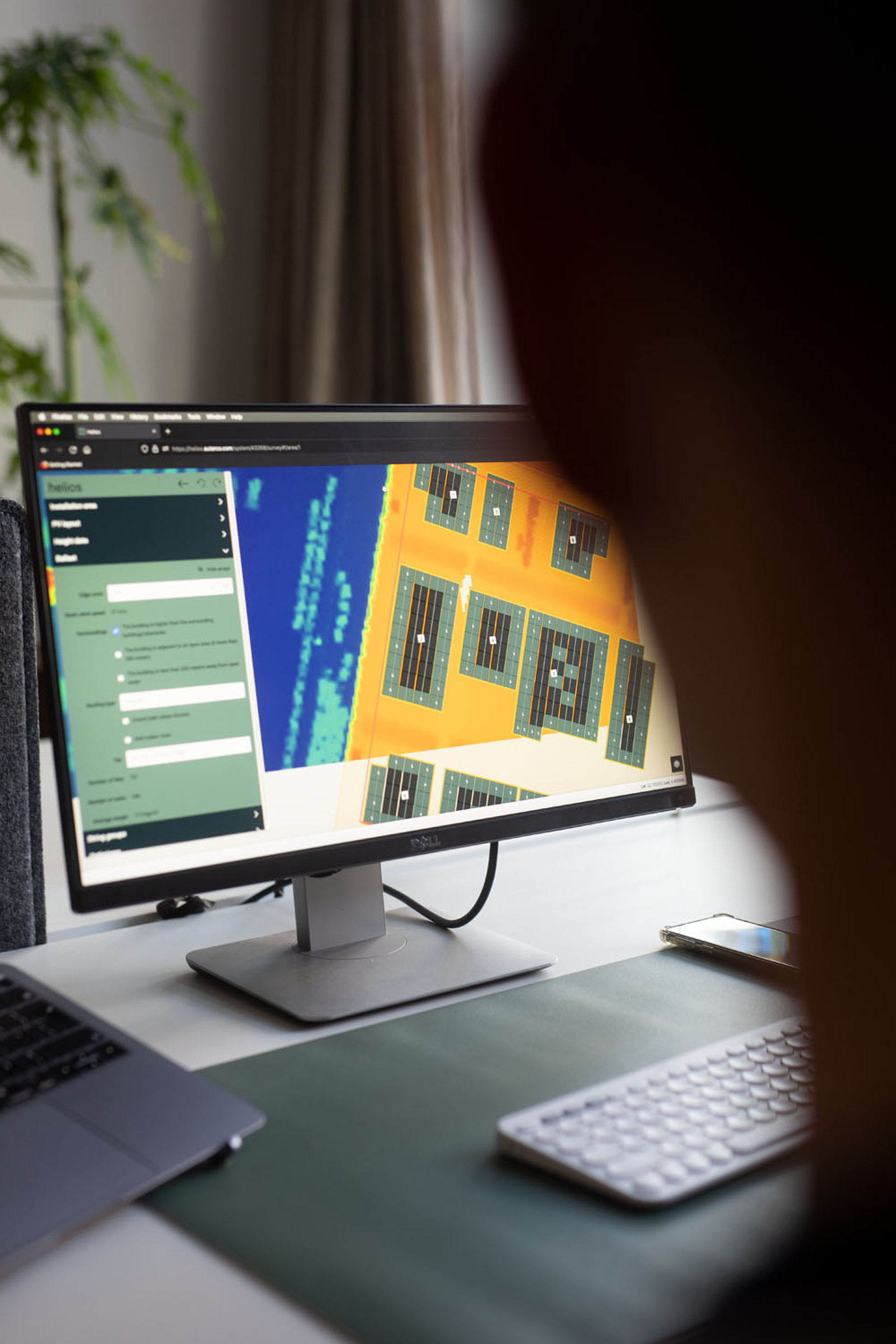

The ‘Digital Twin’ is an exact digital replica of your physical system. It is created in our software, Helios, during the design phase of your project. It forms the basis for the system that will be installed on your roof, the yield we expect the system to have for the kWh guarantee and ultimately the price that the installer asks you to pay.

The ‘Digital Twin’ is designed on top of an elevation map that the designer can adjust to add or remove obstacles. Shade is modeled not only from a chimney on your roof, but also from the tree or hill behind your house.

How do we use the 'Digital Twin'?

Autarco uses the ‘Digital Twin’ to:

- Verify that the installation is made according to the design and that it is correctly positioned. We can achieve a high level of trust through our remote verification, but we also rely on working with the best network of dealers who maintain high quality standards.

- Detect defects or abnormalities that occur during the life of the system.

- In short: the solar power system on your roof must match the calculation of the “Digital Twin” in terms of yield. If this doesn’t happen, something is often wrong.

Simple explanation in layman terms

We are now going to simplify some technical details of the ‘Digital Twin’ using children’s toys.

A solar power system consists of a number of “strings”, which are solar panels that are connected to each other in groups. They usually consist of six to 20 panels, depending on the system size.

In Autarco’s digitized inverters, each string is monitored individually and provides detailed information to our European cloud every five to fifteen minutes.

The information in these messages (voltage, current, power) creates a “shape” that constantly changes based on the actual system design, different shade levels, environmental conditions and possible product defects. You can compare each string in the monitoring message with a 3D block.

Okay cool, but how do this relate to performance monitoring?

At the same time, the “Digital Twin” creates an expectation of the “shape” of each string. To do this, we use data that we receive from different satellites (irradiance, cloud cover and temperature) that we receive every 15 minutes to represent reality as well as possible. We can usually match this satellite data to less than 1 km from your actual location across Europe. Think of the expectation generated by the digital twin as the holes in the ball.

The monitoring messages are the 3D shapes that must fit into the holes. There is a hole and a shape for each ‘string’. If one of the shapes doesn’t fit in the cube, something is wrong and Helios automatically creates a notification in the system. We then check the system for defects.

Who else can do this?

No one.

Autarco is currently the only solar company worldwide that uses this technology.